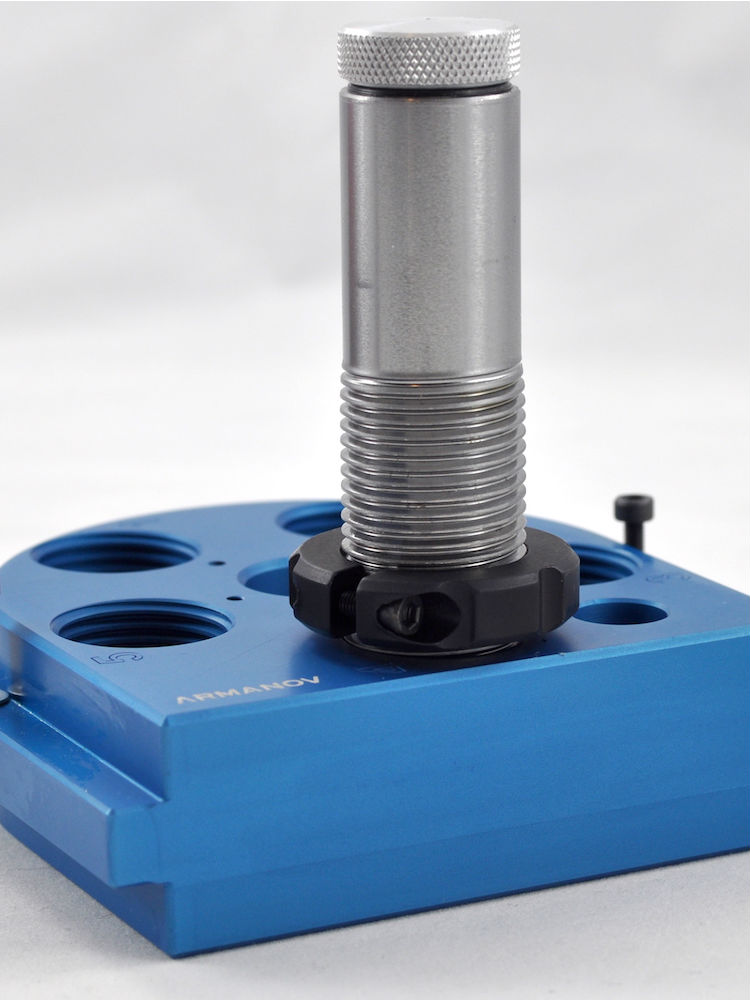

Laget for Armanov sitt Free-Float toolhead til Dillon 650/750 og 550.

De kan brukes som helt vanlig die ringer.

Free-Float die ringer lar size og seat dien flyte, slik at den sentrerer seg til hver hylse for en jevnere og bedre ladning.

Free-Float brukes mest på size og seat dien. Men kan brukes på alle dier om ønskelig.

Passer til:

Alle standard dier

Følger med:

1 stk Die ring

1 stk Låse bolt

1 stk Free-Float bolt

1 stk Unbraco nøkkel

What is Zero Play?

This toolhead does not use original toolhead pins supplied by dillon. This toolhed is bolted with two M3 bolts and lifts toolhead into upmost position. When you cycle cases downwards toolhead does not move and cases go out in straght line. Best practice is to loosen M3 bolts a little bit and push index shell-plate with case in to dies and tighten M3 bolts in toolhed best position.

What is concentricity and what does it matter?

Concentricity refers to how straight the bullet is on top of the loaded round. A bullet that is straight will enter the rifling in the barrel that way. Bullets that enter the rifling slightly crooked do not shoot with their highest accuracy.

What’s wrong with using the OEM toolheads?

The Dillon presses are great machines made to high quality standards. However, the cast toolheads have limitations. How do we know if the toolhead flange is flat? Or how do we know that each threaded station in the toolhead is in perfect alignment with the shellplate? How do we know that the stations are equally spaced? All of these areas compound for possible misalignments and lead to ammunition that isn’t quite as concentric as it could be. The toolhead is the final link between your dies and your press so it only makes sense that quality is extremely important. With over 100,00 EUR of dies, powder measure, and other accessories mounted in your toolhead, don’t you want to know it’s the best available!

What is different about the new CNC Machined Toolhead?

These toolheads are made to the highest standards. The are CNC machined from 6082 aluminum, which is much stronger and has less flex than a cast toolhead. All critical dimensions are machined in a single operation, ensuring that all surfaces are true and aligned relative to each-other. The die holes are positioned with a very high degree of accuracy and the 7/8-14 threads are machined to tight tolerances for precise fit and alignment, yielding dies that are more precisely centered in each hole and better aligned to the cartridge cases in the shellplate. The flange is also flatter than can be achieved with a cast toolhead.

Skyterigg

Skyterigg Skyterekvisita

Skyterekvisita Våpendeler

Våpendeler Optikk & Sikter

Optikk & Sikter Hjemmelading

Hjemmelading